RES - spreader rollers

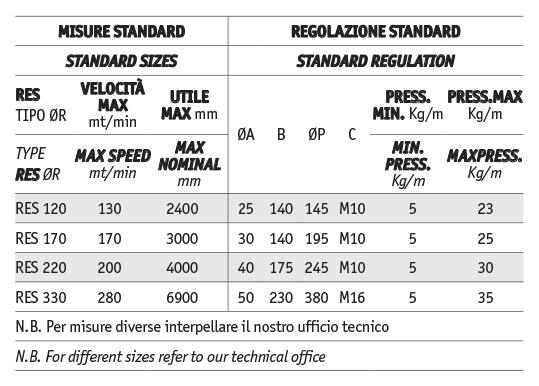

Standard models according to diaemeters RES 120/170/220/330

Application

The RES series spreader roller with elastic cords is generally used to spread and split rigid materials which badly filt the curved roller. These rollers do not have a curved body but a cylindrical one thus eliminating the well-known bending effect when spreading delicate materials with low memory.

Description

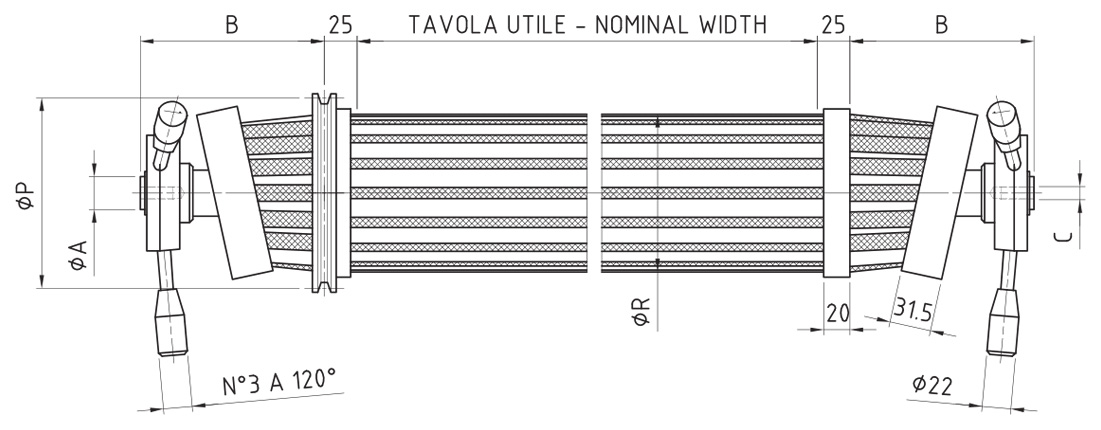

The roller which is made out of an aluminium tube, rotates onto an integral shaft. A series of elastic cords are fitted into special grooves which are cut around the roller surface. These grooves are made in such a way that during the rotation the cords will not come out of their seat because of the centrifugal force effect. The cords, at each end of the roller, are pivoted on a rotary disc which causes them to undergo a different stretching force according to its inclination. The rotor inclination can be adjusted by means of a lever. It is therefore possible to control the spreading effect separately (left side - right side). During a complete turn each single cord undergoes a phase of progressive stretching at up to a maximum extension point after which, without touching the film, each single cord undergoes a phase of progressive concentration back to the starting point. Making the film touch the cords under the stretching phase, the film surface undergoes a progressive spreading effect from the centre towards its external ends which allows to eliminate the film creases.

Mounting

RES roller fixing is a very simple operation. Make two clearance holes into the shoulders and then fix the roller shaft to the internal side of the shoulders by means of two bolts but before fixing it check the rotor position by rotating the roller shaft so that when the cords start stretching they will have to touch the film.

Technical features

The RES series roller is equipped with polyurethane elastic cords. In order to avoid too much crushing of the elastic cords we recommend not to exceed the table maximum pressure value because this would prevent the cords from streching well. Antiozone, solvenf-proof and antiabrasive cords. Indipendent cords for an easy replacement in case of breaking. A special production process ensures a long life to the elastic cords. Rotary capacity in proportion to the different kind of applications.

Operation

Normally the roller rotates beacause of the pulling force imparted by the film running. In such a case the rotary capacity is proportional to the stretching degree set by the operator by adjusting the rotor inclination. For the spreading of light films, which undergo a stretching force lower than the minimum force required for the roller rotation, we can supply a flat or trapezoidal belt pulley which allows the connection of the roller to the pulling force of the operating machine. This pulley can be manufactured with a standard diameter or with different diameter upon customer's request.

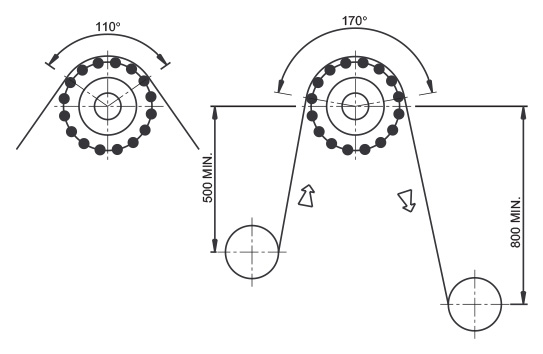

Winding Angle and Distance Between the Rollers

The film winding angle onto the roller must be included between a minimum of 110° and a maximum of 170°. The distance between the RES roller and the following roller must be 800 mm minimum. Under this distance the efficiency of the RES roller reduces.

- Adjustment by indicator of the cord stretching

- Adjustment group mounted on the external side of the machine frames

- Special cords for particular applications

Request more information fill the form:

* Mandatory field